SUSTAINABILITY

THE PATH WE FOLLOW

Nature, mountains, coastlines, forests and meadows – these are the places we find solace, where we tank up on energy. Our employees are our most valuable asset. That is why protecting the environment and people underpins everything we do: Social responsibility, using resources efficiently, short transportation routes and high-quality materials, these are our building blocks. Because we’re not interested in short-term profit maximisation, but instead in uniting business with environmental and social practices, which in turn gives HANWAG the basis for a secure future.

PEOPLE AND MANUFACTURES

Where are HANWAG boots made?

Our footwear is exclusively made in Europe – at our company headquarters in Vierkirchen, as well as at our own production site in Hungary, and at our partner producer in Croatia, with whom we’ve worked for decades and who manufactures exclusively for us. In addition, we cooperate with other long-standing partners in Serbia, Romania, Bosnia and Herzegovina.

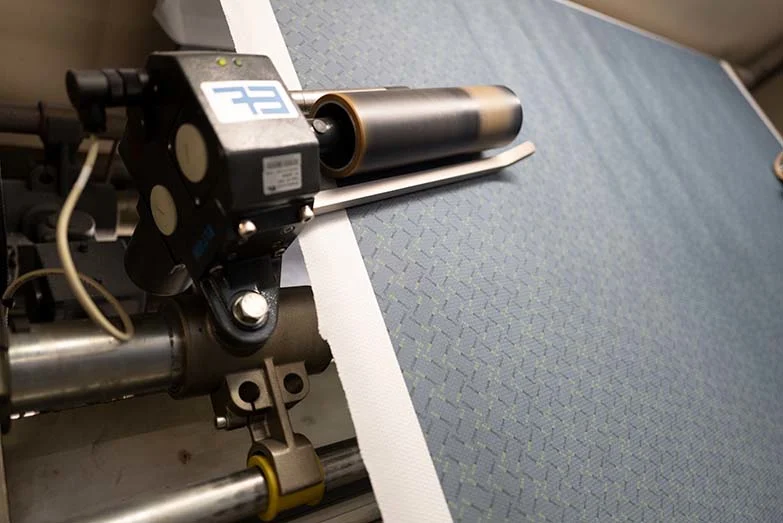

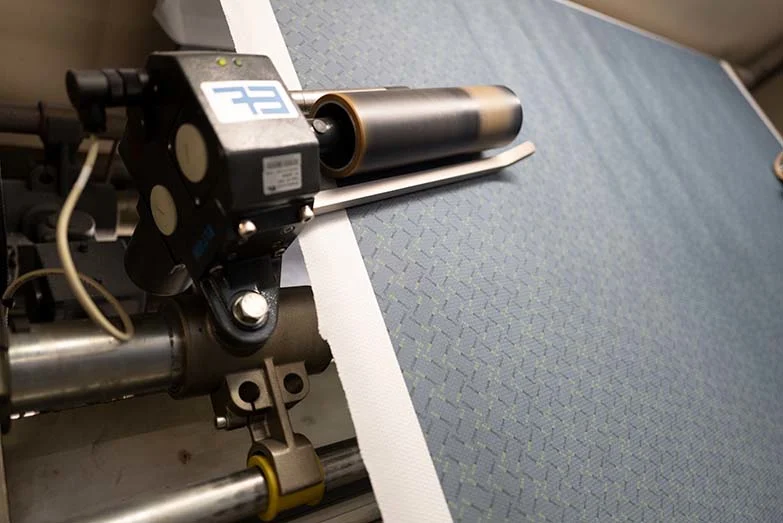

Our footwear production is a complex process that cannot be automated for the most part. Having high quality raw materials is just as crucial as having skilled employees, who understand and are skilled in traditional craftsmanship techniques. We are one of very few manufacturers worldwide to produce most of our models using the cemented construction method. The double-stitched method in particular is only mastered by a handful of shoemakers these days. We are therefore extremely proud of all the employees at our production sites.

Who works at and for Hanwag?

Diversity within the workforce is the guiding principle of our human resources policy. In addition to competence and motivation, ethically and morally correct behaviour is one of the most important qualifying indicators of our employees. We do not discriminate against anyone and do not tolerate any discrimination whether based on gender, ethnic origin, religion, age, disability, sexual orientation, national origin or any other characteristics. Instead, we believe that encouraging diversity enriches us as people and as a company. We have also joined independent initiatives and NGOs. Compliance with social criteria is an indispensable part of our ethical and moral convictions – but also essential for the first-rate quality of our products: We can only achieve the high standards we set for our product range with committed, qualified and happy employees. It is their competence and commitment that are our most valuable assets.

Our parent company, the Fenix Outdoor Group, has been a signatory and supporter of the UN Global Compact since 2012: Based on ten universal principles, it pursues the vision of an inclusive and sustainable economy for the benefit of all people, communities, and markets. The initiative instigated by the United Nations provides a unique framework for achieving a more equitable approach to globalisation across sectors and borders.

We are a member of the Fair Labor Association (FLA), an NGO that aims to improve worker rights and working conditions worldwide. In doing so we have committed to the implementation of the FLA guidelines, and which are monitored throughout the entire supply chain. Once a year, the FLA also carries out an unannounced compliance audit through independent auditors.

RAW MATERIALS AND SUPPLY CHAINS

How is HANWAG’s supply chain structured?

Almost all our raw material suppliers are within the EU. For us, keeping things local is a basic requirement in guaranteeing the quality of our raw materials, keeping transportation routes short and ensuring our manufacturing is of high quality and environmentally responsible. We have been very selective in choosing our partners. They share our conviction that short-term profit maximisation and short-lived relationships are not the basis of success, but rather trust, responsibility and mutual respect.

For many decades, we have maintained close cooperation with suppliers such as the Heinen tannery, for example. This fourth-generation family business is not only a pioneer, but also a driver of the leather industry in terms of socially responsible and eco-friendly processing methods. Under the terracare® brand, they also offer sustainable leather that comes from certified organic farms and is processed in an energy- and resource-efficient way. terracare® leather is used in many of our models, such as the HANWAG Alaska in Earth/Brown.

Which raw materials does Hanwag use?

In addition to our skilled craftsmanship and our sustainable designs, which allows most of our boots to be resoled, high-quality raw materials are essential for us. They must be outstanding in terms of durability and quality.

Recycled materials

We are continuously working to optimise our products and use recycled materials wisely - without compromising on durability. Some examples:

- For the production of the soles, we work together with the specialists at Vibram® and Michelin – drivers of innovation in their sector with a special focus on the use of environmentally friendly materials, technologies and manufacturing processes.

- Our main insole is made of 100% recycled fleece, 100% recycled textiles and 10% recycled viscolatex foam.

- The laces of our Tatra, Tatra Light and Banks models are also made of 100% recycled polyester.

High quality leather

One of our most important raw materials is leather. All the hides we use are a by-product of food production. Products from animals that are killed without being intended for human consumption are not acceptable for our manufacturing. We also refuse to work with partners who do not guarantee animal welfare standards and appropriate slaughtering methods.

We source our leather from selected tanneries, mainly from Germany and Italy. For instance, one of our key suppliers is Heinen, a traditional company whose rawhides come from Germany and are processed in an environmentally friendly way. It also means we can ensure that our leather is free from highly toxic chromium (VI) and has been produced responsibly. Here, you can find out in detail how we use leather in our production.

Wool – traditional material with a feel-good guaranteeEmpty heading

For some of our winter models we use loden, which is a particularly durable wool fabric. We make this using wool fibres from Central and Eastern Europe, which consist of 80% recycled wool and 20% polyamide.

Membranes

In our PFC-free Eco-Shell models we use hydrophilic PU membrane technology with a warm lining made from 100% recycled polyester. For decades, we have used Gore-Tex®, the membrane produced by the US company Gore who have pioneered durably waterproof membranes since 1976. Being able to guarantee functionality over the entire service life of our boots is fundamental for the demanding applications they are used for and our high standards.

Our commitment

We are also a member of various associations, initiatives and organisations dedicated to minimising negative environmental impact.

- HANWAG is a member of the Sustainable Apparel Coalition (SAC). The coalition’s mission is to use the Higg Index to make sustainability quantifiable and transparent to end consumers. There are various tools that can be used along the value chain to achieve this.

- Our parent company, the Fenix Outdoor Group, is a signatory of the UN Fashion Charter for Climate Action (UNFCCC): the United Nations’ international environment treaty aims to prevent dangerous disruption of the climate system, slow down global warming and mitigate its consequences.

- The Fenix Outdoor Group is also a member of the Swedish Textile Initiative for Climate Action (STICA), which strives to help apparel and textile organisations reduce their climate impact while strengthening their global competitiveness.

- In the North American market, we cooperate with the Outdoor Industry Association's Climate Action Corps which means we commit to measuring and reducing our CO2 emissions and sharing our progress yearly.

RESPONSIBILITY WITH TRADITION

When Hans Wagner started making shoes and boots in 1921, a careful and conscientious approach to materials and ensuring their high quality was absolutely essential. Not necessarily for environmental concerns. But one thing was clear: you could only be successful as a craftsman if you created a product that was durable and reliable.

Hans Wagner's rapid success was based on his reputation for making high-quality mountain boots with an elaborate construction. This meant that the boots could be resoled if the soles were worn. The uppers could be reused. And people got more for their money. To this day, this approach is still characteristic of HANWAG.

Most of our boots are cemented or double-stitched. The processes are complex and correspondingly more expensive than conventional methods. But it is only with these types of construction that it’s possible to resole them – and therefore create lasting products. In 2020, 15,635 pairs of HANWAG boots were resoled. The most sustainable product is the one we already have – and will have for a long time to come.

Of course, we have always been very selective in selecting our raw materials as well. It's about achieving the best quality and ensuring the production is as local as possible environmentally friendly. In this way, we not only create the highest quality, most durable footwear, but also save resources and protect the environment. For us, this isn’t some new strategic idea, it has simply always made sense for the work we do.

In order to keep transport routes short and CO2 emissions low, we produce in our own manufacturing facilities and with local companies working exclusively for HANWAG. All stages in the process – from research and development, raw material production and supply, to manufacturing – take place within Europe.

This presents numerous opportunities to further develop our tradition of sustainability in a contemporary and forward-looking way, with new technologies and solutions. The aim is not only to make mountain, trekking and hiking boots even better. But also to express our love for nature by leaving it in good condition for generations to come.